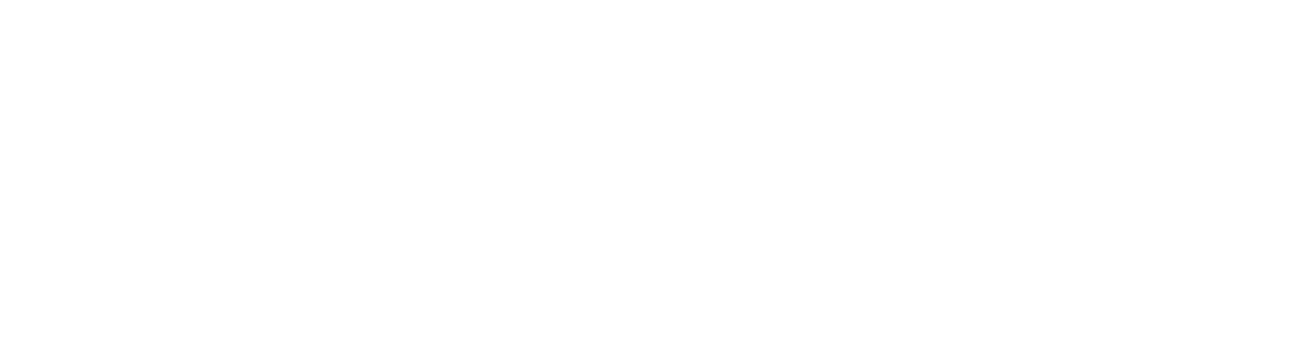

Machining

Under the long experience and ISO9001 management system, we deliver molds with high precision, high performance, and long life for customer needs.

Processing and Manufacturing

By using main equipment such as NC lathe and machining, we manufacture processed products such as molds, parts, and jigs.

Japanese technical staff are also permanently stationed, and we support you with Japanese quality.

By enhancing various inspection equipment, we adjust the assurance system for high-precision products and aim higher.

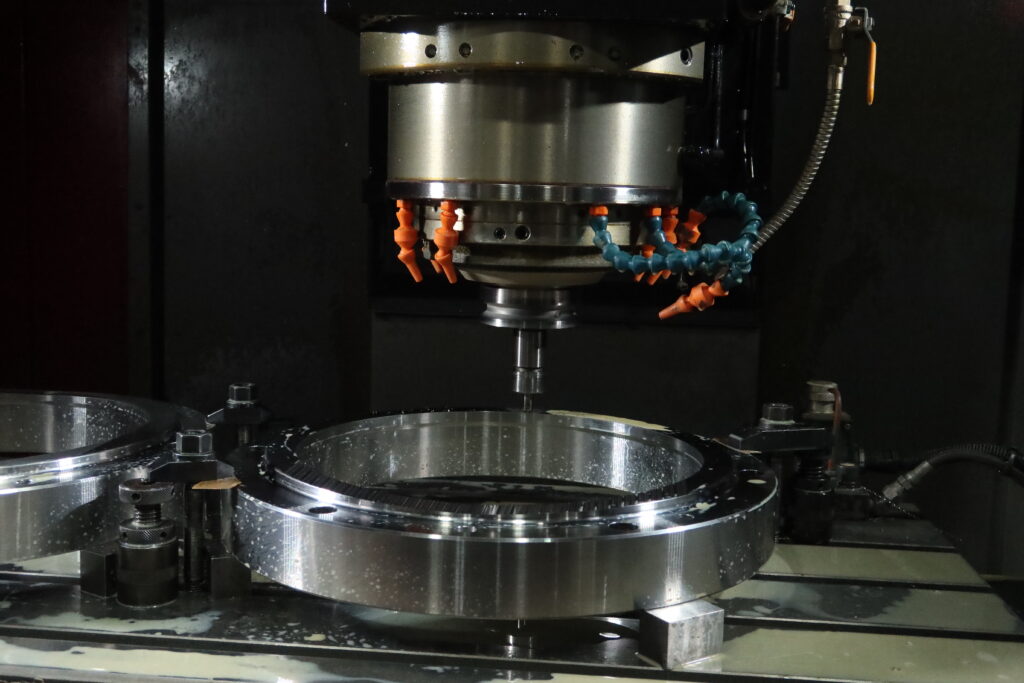

Reverse engineering

By measuring the actual product, digitizing, and drawing with the non-contact coordinate measuring machine (Digitizer), CAM data creation, machining, and inspection can be performed consistently. Therefore, the mold can be duplicated.

Since the non-contact coordinate measuring machine (Digitizer) is a movable type, it is possible to measure at the customer’s site.

Digitizer is used for:

・Measurement assurance of the entire surface

(Mold, Customer’s product, Electrode for electric spark machining, etc.)

We meet multiple needs such as visual evaluation of distortion and warpage, significant reduction in measurement time, and description as colormap.

・Reverse engineering

(Mold is manufactured from the measured product.)

Quality assurance

Various inspection equipment is installed.

Under the guidance of Japanese technicians, we deliver reliable peace of mind to our customers.

We regularly check the accuracy of machine tools and measuring equipment.

Moreover, we strive for quality assurance and stable supply in each process and final inspection.

We have equipment to ensure quality such as contact coordinate measuring machine.

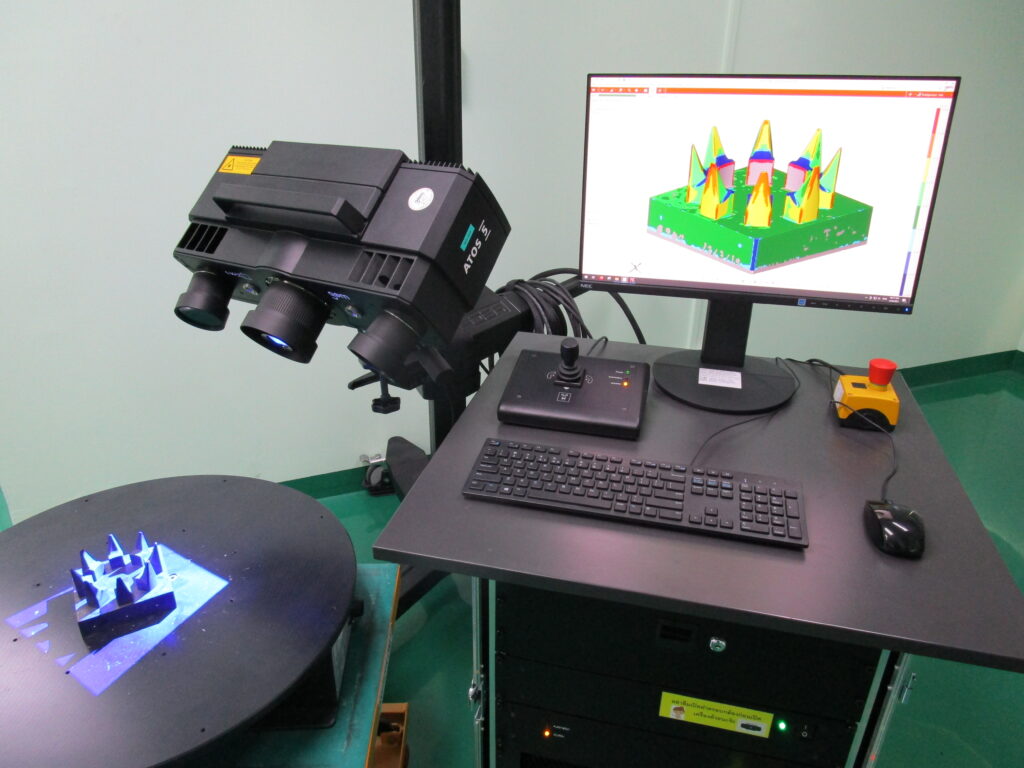

Machining equipment

| Eqipment | Model | Manufacturing company | Unit | Usable dimension (mm) |

|---|---|---|---|---|

| Vertical machining center | VM53R | NIDEC OKK | 1 | 1000x500x500 |

| Vertical machining center | VB53R | NIDEC OKK | 1 | 1000x500x500 |

| Horizontal machining center | HM630 | NIDEC OKK | 1 | 1000x900x900 |

| CNC lathe machine | NLX2500/700 | DMG MORI | 1 | φ280x700 |

| CNC lathe machine | SL-303/700 | DMG MORI | 1 | φ280x700 |

| 5-axis compound lathe machine | NTX1000 | DMG MORI | 1 | φ140 (450x200x700) |

| Vertical lathe machine | V760EX | OKUMA | 1 | φ670×770 |

| Wire electric discharge machine | α-1iE | FANUC | 1 | 600x400x300 |

| Gun drill machine | MLEG-1000S | MIROKU | 1 | φ6-25 (540x240x800) |

| Surface grinding machine | PSG126DX | OKAMOTO | 1 | 1200x600x500 |

| Surface grinding machine | ACC64SA1 | OKAMOTO | 1 | 600x400x300 |

| Cylindrical grinding machine | GUP32x100 | JTEKT | 1 | φ280 x 1000 |

| Small hole electric discharge machine | K3HS | SODICK | 1 | 300x400x450 |

| Hydraulic press | KPD-500VS | OSAKA JACK | 1 | 500t (500x500x450) |

| KPD-1000VS | OSAKA JACK | 1 | 1000t (600x600x460) | |

| Digitizer | ATOSⅡ Triple Scan | GOM | 1 | 500x420x420 |

| ATOS 5 | GOM | 1 | 550x320x200 | |

| CMM | CONTURA 7106 | CARL ZEISS | 1 | 700x700x600 |

| Contour machine | CONTURECORD 2600G | ACCRETECH | 1 |